|

|

|

|

|

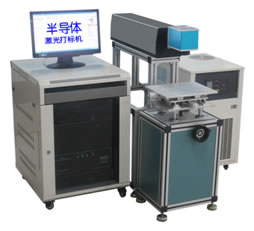

Diode End-pumped Laser Marking Machines |

|

To meet the growing demand for industrial precision

processing, we have creatively developed the diode end-pumped Q-switched

laser marking machine. It is air-cooled, small, compact and low power

consumption. The laser beam is TEMoo with high beam quality, high peak

power and short pulse width. Excellent resonator design can keep average

laser power and pulsed peak power stable & constant. This laser machine

can meet the requirements of most industrial precision processing.

Comparison between our End-pumped Laser Marker and other

Laser Markers:

|

Machine Type |

M2 |

Frequency |

Min line width |

Power consumption |

Features |

|

End-pumped

(Air-cooling) |

<1.2 |

<50kHz |

35μm |

<0.5kw |

Long lifetime,

Maintenance-free |

|

Side-pumped

(Water-cooling) |

<3 |

<10kHz |

90μm |

<2.0kw |

Exchange water per 3 months |

|

Fiber laser

(Air-cooling) |

<1.5 |

20k~50kHz |

20μm |

<0.5kw |

Short lifetime,

High price |

|

Lamp-pumped

(Water-cooling) |

<10 |

<10kHz |

60-120μ |

<5.0kw |

Exchange lamp per 2000 hrs |

The above table shows that end pump laser marking machine

is significantly better than any other mainstream markers whether in

terms of laser characteristics or in the use and maintenance.

Main Technical Characteristics:

(1)Air

cooling, small size and compact.

(2)TEM00,

high beam quality, M�≤1.2, can mark fine lines, suitable for high

precision marking applications.

(3)High

quality Q-switch, narrow pulse width, high peak power, high power

stability, subtle thermal ablation.

(4)High

pumping efficiency with fiber coupled diode laser and long lifetime

(20,000 hrs).

(5)Laser

is airproof via vacuumized.

(6)High

performance price ratio.

Applications:

End-pumped diode laser marking machine is suitable for

marking on various materials, such as nylon, ABS, PVC, PES, steel,

titanium, copper, plating materials, coating materials, sprayed

materials, plastic, rubber, epoxy resin etc.

And it can mark character, pattern, batch number,

production date, bar code, logo etc.

End-pumped diode laser marking machine has excellent

performance in different fields, such as cellphone, jewellery, crafts,

scribing, film engraving, laser marking

& engraving, resistence trimming, distance measuring, scientific

research etc.

Technical Specifications:

|

Model |

M-DPSS-5 |

M-DPSS-10-IL |

M-DPSS-12 |

M-DPSS-15-IL |

M-DPSS-20-IL |

M-DPSS-25-IL |

M-DPSS-30-IL |

|

Laser |

DPSS-532-5 |

DPSS-1064-10-IL |

DPSS-1064-12 |

DPSS-1064-15-IL |

DPSS-1064-20-IL |

DPSS-1064-25-IL |

DPSS-1064-30-IL |

|

Wavelength |

532nm |

1064nm |

1064nm |

1064nm |

1064nm |

1064nm |

1064nm |

|

Laser power |

5W |

10W |

12W |

15W |

20W |

25W |

30W |

|

Beam quality |

M2<1.2 |

M2<1.2 |

M2<1.2 |

M2<1.2 |

M2<1.4 |

M2<1.6 |

M2<2 |

|

Power stability |

<2% |

|

Modulation |

1kHz-200kHz |

|

Pulse width |

8-40ns |

|

Peak power |

25-200KW/10KHz |

|

Power supply |

220VAC/50Hz |

|

Environment |

15℃~30℃

(no dewing) |

|

Mark area |

70�70, 110�110, 150�150, 175�175 mm2

or others |

|

Power input |

600W |

600W |

700W |

700W |

800W |

1200W |

1200W |

|

Cooling |

Air |

Water |

|

|

|

|

OEM Diode-pumped

Nd:YAG Laser Markers (50W, 75W or higher) |

|

|

|

We can provide OEMs and system integrators with a range

of high performance components and sub-assemblies of diode-pumped Nd:YAG

laser markers at more attractive prices. These components and

sub-assemblies include laser head (diode pump module, laser resonator,

Q-switch cell),

Q-switch

driver, diode driver, marking

head, marking software, chiller,

stage. |

| |

|

Model Number |

Description |

Option |

|

M-DPSS-50OEM |

50W

laser marker, including laser head with mark head

LSCT-1064-12-110-6231, diode driver LDD3018, Q-switch driver QSD2750,

electrical controller STCB18, marking card and marking software

LMX-1 |

chiller

ST-LW16-BHP |

|

M-DPSS-75OEM |

75W

laser marker, including laser head with mark head

LSCT-1064-12-110-6231, diode driver LDD3024, Q-switch driver QSD2775,

electrical controller STCB18, marking card and marking software

LMX-1 |

chiller

ST-LW16-BHP |

Remark:

marking head LSST can be used to replace marking head LSCT at much

lower prices. Marking card is also called as D/A card.

|

|

1) Laser

Head with Marking Head |

|

|

|

A laser head consists of

laser base (optical rail),

pump module,

output

coupler and rear mirror with mount, beam expander,

AO Q-switch cell,

front plate, rear plate, and cover (option:

aperture with mount). A laser marking head consists of scan mirrors,

galvanometers & drive cards,

galvanometer mount,

scan lens (f-theta

lens), marking card (PCI slot), marking software (under Windows XP)

and DC power supply. |

|

|

|

|

|

|

|

2.

Q-switch Driver |

|

|

|

The panel

is standard 19 inch. |

|

|

|

|

|

3.

Diode Driver |

|

|

|

The panel is standard 19 inch.

|

|

|

|

4.

Electrical Controller |

|

|

|

Including

DC power supply of the marking head, replays, buttons, indicators,

alarms etc.

|

|

5. Chiller |

|

Remark:

diode

driver, Q-switch driver and electrical controller can be integrated into

a 19� box (called as �3 in 1� laser driver). The whole OEM laser marker

just consists of a laser head with a marking head, a 19� box and an

optional computer.

|

| |

|

Integrated Diode-pumped

Nd:YAG Laser Marking Machines (50W, 75W or higher) |

|

|

|

Our DPSS laser marking systems are made

by our experienced engineers. Their performance is comparable with

similar products in the world, but their prices are very attractive and

competitive. These laser marking systems are widely used in industries

such as electronics, semiconductor and precision machining for laser

marking and trimming on moving objects, flat and cylindrical surfaces. Our DPSS laser marking systems are made

by our experienced engineers. Their performance is comparable with

similar products in the world, but their prices are very attractive and

competitive. These laser marking systems are widely used in industries

such as electronics, semiconductor and precision machining for laser

marking and trimming on moving objects, flat and cylindrical surfaces.

(Reference:

Laser Marking Mechanism &

Quality Characteristics &

How to Select a Laser Marking System)

|

|

Model |

M-DPSS-50

|

M-DPSS-75

|

|

Laser Head |

|

Laser type |

Diode-pumped solid-state lasers

|

|

Laser wavelength |

1064nm

|

|

Beam diameter |

3mm

|

3mm

|

|

Beam mode |

TEM00

or low-order

|

TEM00

or low order

|

|

Laser power |

50W

|

75W

|

|

Power stability |

�1%

|

�1%

|

|

Q-switch frequency |

Max. 50kHz

|

|

Cooling requirement |

Chiller

|

Chiller

|

|

Electrical requirements |

220VAC, 2KVA

|

220VAC, 3KVA

|

|

Marking

Head |

|

Scanner |

High-speed optical galvanometers

|

|

Marking field (mmxmm) |

100x100 (other

mark fields available upon request)

|

|

Marking speed |

300

characters/second or 10m/s

|

|

Marking line (mm) |

Min. 0.01

|

|

Dimension |

210�138�120mm

|

|

Marking software |

|

Various fonts, pictures (PLT, DXF, BMP),

automated series numbers, barcodes, DataMatrix, time, date |

|

Options |

|

Lab jack, Z stage |

|

* Marking

field depends on scan

lens (f-theta lens) once other parameters and parts are confirmed.

Large field sizes demand the use of lenses of long focal length. In

turn, this leads to increase focused spot size and decrease laser

power density on the workpiece. Thus reasonable mark field should be

carefully selected. If both small focused beam diameter (narrow line

width) and large field are simultaneously required, a XY

moving table is recommended for best performance.

* Other Nd:YAG lasers

& customized laser marking systems available upon request. |

|

|

|

|

|

Diode-pumped Nd:YAG Laser Deep Engraving System |

|

The laser is specially designed for deep engraving on

metals. The laser can output long pulse width & high power energy, also

can output short pulse width & high peak power for the deep engraving of

different materials. Through the application of new technology, the peak

power is around 10 times compared to the traditional lasers, reaching

300kW. High beam quality and high conversion efficiency make the laser

the best choice for deep engraving applications. The engraved depth can

reach 5mm.

The laser can be used in deep engraving of parts of

automotive and motors, hardware tools, stainless steel products, medical

parts, clock and watch, industrial bearing, mould. The materials to be

engraved include copper, brass, aluminum, alloy, stainless steel etc.

We can

provide OEMs and system integrators with a range of high performance

components and sub-assemblies of deep laser engraver at more attractive

prices. These components and sub-assemblies include laser head with

marking head, Q-switch driver,

diode

driver,

marking software and chiller.

|

Machine model |

M-DPSS-30DEEP |

|

Laser wavelength |

1064nm |

|

Average power |

32W@CW, 10W@2kHz, 21W@5kHz, 26W@10kHz, 28W@20kHz |

|

Laser pulse width |

26 - 300ns |

|

Laser pulse energy |

4.8mJ@2kHz, 4.12mJ@5kHz, 2.6mJ@10kHz,

1.38mJ@20kHz |

|

Laser peak power |

119kW@2kHz, 64kW@5kHz, 34kW@10kHz, 1kW@20kHz |

|

Beam qualityM2 |

M2≤1.5 |

|

Beam modulation |

1kHz - 50kHz |

|

Laser power stability |

≤2% |

|

Cooling |

Water |

|

Electric supply |

220VAC/50Hz |

|

Environment |

15℃

- 30℃ |

|

Engraving linewidth |

0.2~0.5mm |

|

Engraving field (mm2) |

70�70, 110�110, 150�150, 175�175 or others |

|

Maximum engraving depth |

5mm |

|

Software feature |

Various fonts, pictures (PLT, BMP), automated

series numbers, barcodes, DataMatrix |

|

Options |

Z-axis adjustable stage, XYZ-axis adjustable

stage, chiller |

|

|

Typical

Applications:

|

|

|

|

1. Laser marking of metal &

non-metal materials and products: stainless steel, copper, aluminum alloy,

acrylic, ceramics, plastics, organics, thermo-elastomer

rubbers, paper, scissors,

bearing, gear,

detonator |

|

2. Electronic industry: capacitor,

inductor, oscillator, PCB,

IC, connector,

control panel, instrument |

|

3. Others: cosmetics, food package,

bottle, gift, advertisement &

signcrafts, craft & gift making |

|

4. Marking on flat and

cylindrical surfaces, moving objects. |

|

|

|

Lamp-pumped Laser Markers Fiber

Laser Marker CO2 Laser Markers

Jewelry & Ring Laser Marker Lamp-pumped Laser Markers Fiber

Laser Marker CO2 Laser Markers

Jewelry & Ring Laser Marker

Dual-head Laser Marker

UV Laser Marker |

|

Download datasheet

"Diode-pumped Nd:YAG

Laser marking systems" in PDF |

|

(Reference: Laser Marking Mechanism &

Quality Characteristics &

How to Select a Laser Marking System) |

|

|

|

|