|

(Cleaning,

Marking, Deep Engraving & Cutting)

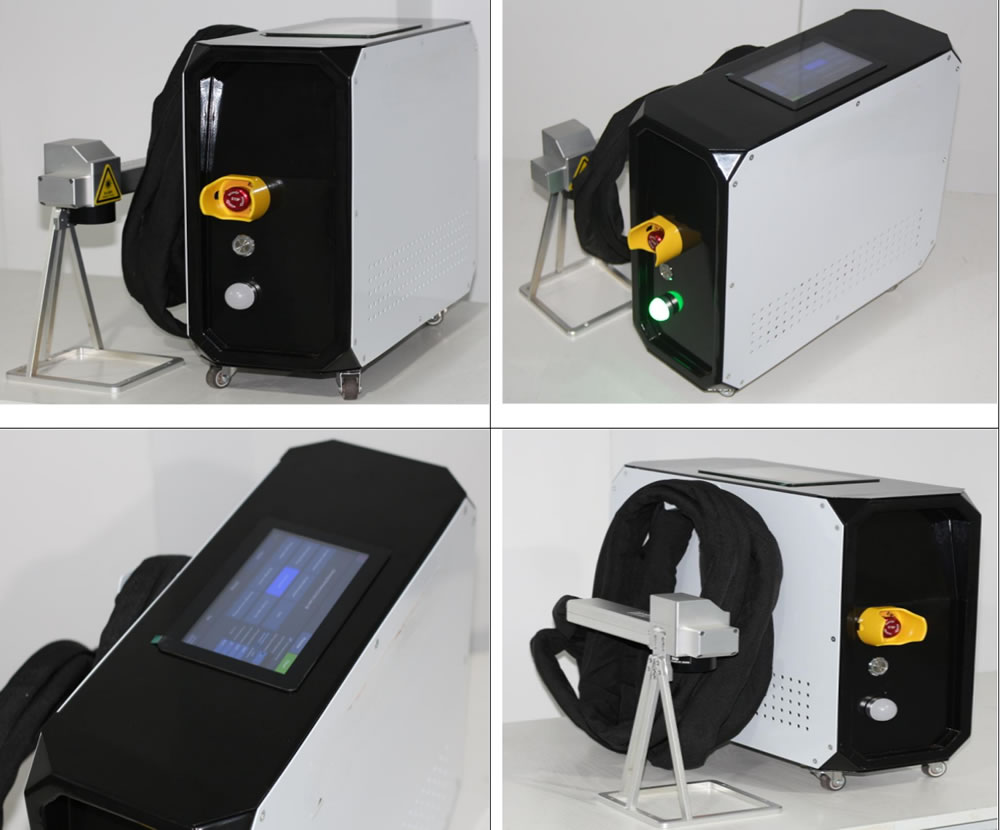

The pulse

laser cleaning machine mainly consists of MOPA cleaning laser, control

board, control system, pulse cleaning dual swing cleaning head, cleaning

f-theta lens, power supply, housing, etc.

Features:

The machine casing is made of metal sheet,

laser cut, welded and polished, suitable for various harsh working

environments with a beautiful and durable appearance.

-

Full body metallic

paint, smooth and bright surface, bright color, high temperature

resistance, corrosion resistance, impact resistance, friction

resistance, waterproof and oil resistant.

-

Metal start switch

and metal power interface have a long service life, sensitive

response, good contact conductivity, and can be used in harsh

working environments.

-

The fiber optic

protective cover adopts high-density fibers, which are fireproof,

waterproof, and corrosion-resistant, and can effectively protect the

fiber optic from long-term use in various harsh environments.

-

This laser is

produced by the well-known company, which has a uniform optical mode

and stable laser output energy. Flat top light design, energy

density of 5mJ, low power consumption for air cooling.

-

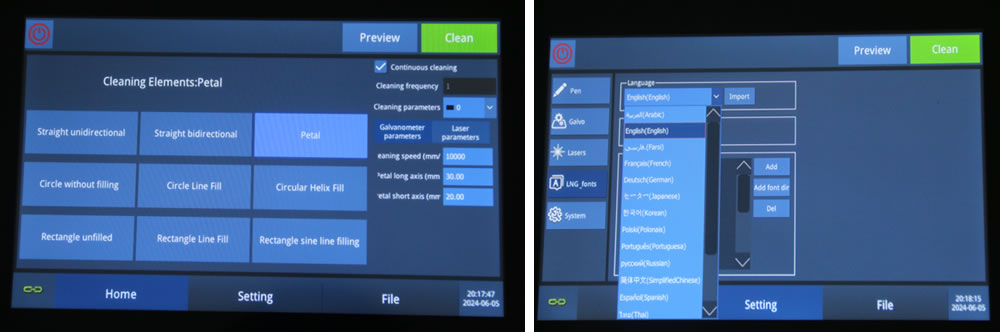

The control system

adopts a high-sensitivity capacitive touch screen with fast response

speed. There are 9 cleaning methods including straight line, circle,

petal, solid circle filling, horizontal and vertical scanning, and

20 global languages. The interface operation is simple and easy to

set, and can adjust laser power, frequency, pulse width, graphic

size, cleaning speed, and reaction time.

-

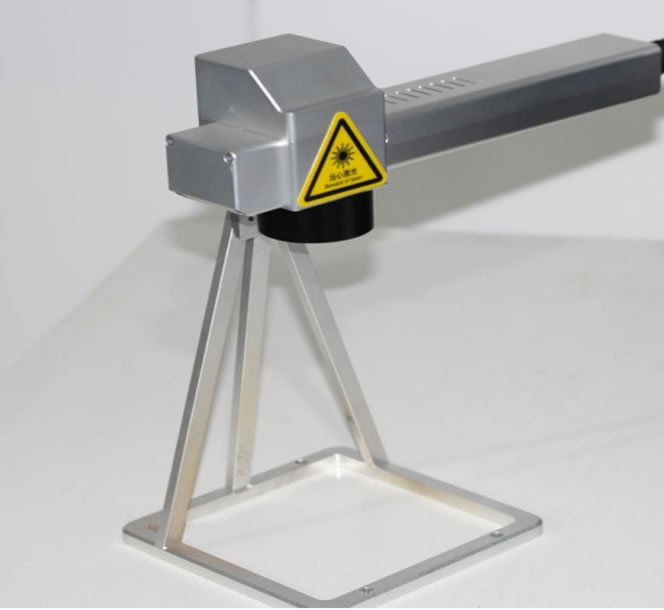

The cleaning head

weighs 500g, with a dual swing X/Y copper wire motor. The lens is

made of high-temperature quartz material with silicon chips, which

does not heat or deform. The fixed bracket is distributed for easier

cleaning operation.

Specifications:

|

Part number |

SKR-C200W |

|

Laser power |

200W |

|

Max. pulse energy |

5mJ |

|

Laser type |

Fiber MOPA |

|

Laser wavelength |

1080nm |

|

Power range |

0--100% |

|

Pulse repetition rate |

1-3000KHz |

|

Pulse width |

13--500ns |

|

Power non-stability |

<5% |

|

Laser beam divergence |

≤1.5mrad |

|

Laser cleaning width |

1-100mm |

|

Focal length |

F=200mm |

|

Cleaning modes |

9 modes |

|

CW operation time |

16hours |

|

Machine noise |

≤60db |

|

Fiber length |

5M standard |

|

Electrical input power |

≤ 1KW |

|

Power supply |

AC110/220V±10% 50Hz/60Hz |

|

Operation temp. |

-10°C-40°C |

|

Cooling method |

Air |

|

Machine weight |

20kg |

|

Machine dimension |

450*170*360mm |

|

Pack (wooden) |

490*210*480mm, 28kg |

Control

system:

Adopting a 7-inch capacitive touch screen and microcontroller principle,

it can set laser power, laser frequency (pulse repetition rate), pulse

width, cleaning width, filling angle and spacing, 9 cleaning modes, and

20 languages. It is compatible with marking systems.

Handheld

cleaning head (compatible with marking function):

All metal 6061 aluminum alloy design and manufacturing, electroplated

frosted silver, comfortable grip, wear-resistant and drop resistant, gun

body weight of 750 grams, long-term holding without fatigue; The gun

body is equipped with metal buttons, with over 500000 clicks. It

features a copper high-speed motor with dual mirrors, a heavy load

accuracy of less than 5urad, a positioning speed of 20m/s, and is

suitable for temperatures ranging from -20 ° C to 60 ° C with high speed

drive 20000Hz/s, fast response speed, small error, and no noise.

High-quality quartz lens is durable and long-lasting. Equipped with a

special positioning device bracket for precise focusing, it is easier to

operate during cleaning, and can also be disassembled by oneself. It can

switch the handheld marking function with one click, perfectly

integrating handheld cleaning, marking, thin-metal cutting, and deep

engraving.

Cleaned Samples: |