STRM-QPT: 3D Post-Scanning

Solution

(Refer to STRM-Q Quantum datasheet for 2D galvo.)

This solution includes a 2D galvoscanner system STRM-Q Series, a dynamic

focus unit Proton Series, F-theta lens and a galvo system controller

STRM-UMC4. It uses the Post-Objective Scanning technology, the working

volume is about 150*150*45(with the 210mm F-theta lens). The advantage of

this system: marking fast, small focal spot, small loss.

| Laser type |

Nd:YAG |

Nd:YAG doubled |

| Wavelength |

1064nm |

532nm |

| Beam expansion factor |

1.67 |

3 |

| Input aperture |

6mm / 7.2mm / 8.4mm |

3.3mm / 4mm / 4.6mm |

| Scan head apertures |

10 / 12 / 14 |

10 / 12 / 14 |

| Focus range in Z-direction

|

�22.5mm (1) |

�2.5mm (2) |

| Tracking error time |

700us |

700us |

(1) F-Theta f=210mm. (with F-Theta objective

,f=210mm)

(2) F-Theta f=100mm. (with F-Theta objective ,f=100mm)

All of the above parameters are theoretical values.

STRM-QP 20/30: 3D Pre-Scanning Solution

(Refer to STRM-Q 10/ 12/ 14 datasheet for 2D galvo.)

STRM-QP 20/30: 3D Pre-Scanning Solution includes a 2D galvoscanner system

STRM-Q, a dynamic focus unit Proton series, and a galvo system controller

STRM-UMC4. It uses the Pre-Objective Scanning technology to realize the

large field and 3D laser application. The advantage of this system: fast,

small focal spot, small power loss.

CO2 laser configuration example: STRM-QP 30

|

Working

dimension |

600x600mm |

600x600mm |

|

Spot

diameter |

364um |

487um |

|

Working

distance |

502mm |

777mm |

|

Resolution |

9um |

12um |

Nd:YAG laser configuration example: (λ=1064nm) STRM-QP20/ 30

| Working dimension |

400x400mm |

600x600mm |

800x800mm |

| Spot diameter |

| QP-20 |

34um |

52um |

- |

| QP-30 |

- |

36um |

48um |

| Working distance |

| QP-20 |

502mm |

777mm |

- |

| QP-30 |

- |

777mm |

1051mm |

| Resolution |

6um |

9um |

12um |

UV laser configuration example: STRM-Q14 + Proton

|

Working

dimension |

400x400mm |

600x600mm |

|

Spot

diameter |

17um |

26um |

|

Working

distance |

520mm |

795mm |

|

Resolution |

6um |

9um |

1. All of the above parameters are theoretical values.

2. Distance between edge of deflection unit and working surface. This

distance is dependent on the product model and will vary with laser

divergence and objective tolerance.

3. Actual spot size and writing speed are dependent on material and

application.

Typical

applications:

Typical

applications:

� Drilling,

cutting, welding

� Laser deep

engraving

� Rapid

prototyping, rapid tooling

�

Micro-structuring

� 3D work piece

processing

Optics in

motion

The dynamic

focusing units of the LSSL-DNF series enable exceptionally precise,

high-performance positioning of the laser focus along the optical axis.

In XY scan

systems this unit can replace costly flat field objectives. Therefore, the

unit is an ideal solution in applications for which standard flat field

objectives are unavailable. The LSSL-DNF series can also extend XY scan

systems into 3D beam deflection systems. The laser focus is guided along the

contour of the work-piece being processed, thus enabling processing in three

dimensions. The dynamic focusing unit additionally allows continuously

adjusting the image field size, working distance and spot size. The high-end

member of the LSSL-DNF series of focusing units is equipped with a digital

linear encoder.

The LSSL-DNF

series offers double the maximum travel of previous product and much lower

tracking error, resulting in a larger focus-shift range and better spot

quality. Its accuracy, speed, resolution and linearity, too, are clearly

superior to those of all other units, while substantially eliminating the

effects of drift. In addition, this unit delivers all advantages of driving

technology: extensive flexibility, high dynamic performance, real-time

querying of actual position and other status parameters, etc.

The LSSL-DNF

series offers double the maximum travel of previous product and much lower

tracking error, resulting in a larger focus-shift range and better spot

quality. Its accuracy, speed, resolution and linearity, too, are clearly

superior to those of all other units, while substantially eliminating the

effects of drift. In addition, this unit delivers all advantages of driving

technology: extensive flexibility, high dynamic performance, real-time

querying of actual position and other status parameters, etc.

How it Works

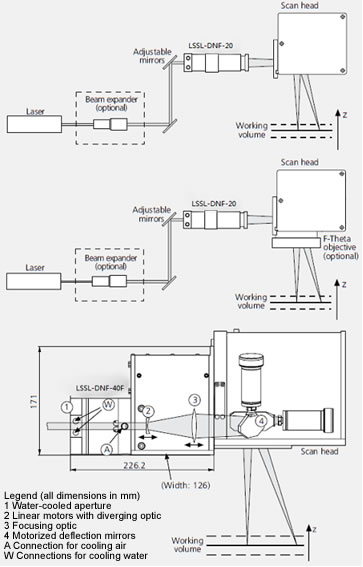

During the

scanning process, a diverging optic in this module is positioned with high

dynamics along the optical axis with respect to a stationary focusing optic.

This produces a change in the system�s overall focal length, synchronized

with the mirror motion. The dynamic focusing unit can thereby expand 2D scan

systems into 3-axis scan systems. In 2D applications, this module can

replace costly flat field objectives. In 3D beam deflection systems it

enables processing in three dimensions.

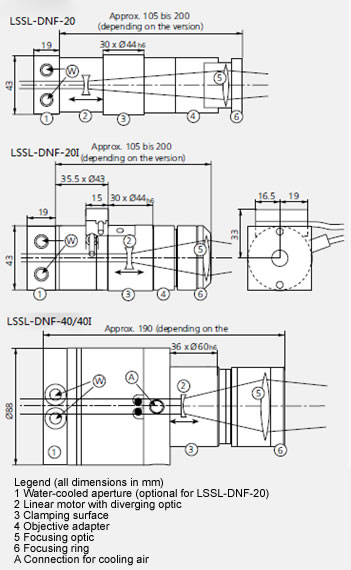

The focusing

optic of the LSSL-DNF-40F is motor-driven, enabling continuously variable

image field sizes and working distances. The LSSL-DNF-40F housing contains

all optical components and the electronics. For scan systems with apertures

exceeding 40 mm, we offer LSSL-DNF-60, 60I, 80 and 80I and the LSSL-DNF-FC.

Control

The dynamic

focusing unit is equipped with a digital standard interface and is easily

controlled � even synchronously with a 2D PC-based interface board scan

system. The module is available for digital and analog-based control.

Optics

We offers

dynamic focusing unit and the whole scan system � optical configurations for

a wide variety of working distances, image field sizes, beam diameters,

wavelengths and laser powers for optimally tuning the system to the

customer�s particular application. Thus, a maximum image field size is

achieved with the minimum spot size.

The

LSSL-DNF-40 and LSSL-DNF-40I allows the customer to self-install various

exchangeable optics sets. Their integrated air and water cooling ensure

operation at very high laser powers. The LSSL-DNF-20I is equipped with a

water-cooled entrance aperture.