|

1.

Fiber-delivered

Laser Welding Machine

The optical fiber delivery laser welder is a kind of

laser welding equipment that couples the high energy laser beam into the

optical fiber, collimates to parallel light by collimating lens after

long distance transmission, and then focuses on the work piece to weld.

For the positions hard to reach, implement flexible noncontact welding

to have more flexibility. The laser beam can realize spectroscopy in

time and energy and process multiple light beams simultaneously, making

more precise welding possible.

Features:

1.

CCD monitor system is equipped for observing and

precision positioning.

2.

The welding spot energy distributes evenly and has the

perfect light spots required by welding characteristics.

3.

Suitable for complex welds, spot welding of different

devices and seam welding of thin plates within 1mm;

4.

Ceramic converging cavity is imported from the Britain.

It is corrosion resistant and high temperature resistant, and has 8-10

years service life. The life of xenon lamp is more than 8 million times.

5.

Automatic tooling fixtures can be customized to realize

mass production.

|

Model |

WF300 |

|

Laser wavelength |

1064nm |

|

Laser working substance |

Nd:YAG |

|

Pulse width |

≤40ms |

|

Pulse frequency |

≤80Hz |

|

Optical fiber diameter |

0.4mm/0.6mm |

|

Minimum welding spot diameter |

0.2mm |

|

Rated laser power |

300W/400W |

|

Optical fiber output quantity |

Both energy spectroscopy and time spectroscopy

are available; standard optical fiber: one line, up to six lines |

|

Cooling system |

Water cooling |

|

Power supply |

380VAC�10%/50Hz, 14kW |

|

Dimensions |

1200x600x1100mm |

|

Weight |

300kg |

Laser welding is the most flexible and modern method to

join together different materials. With STCP welding machine, it is

possible to weld together metals, such as steel, stainless steel,

platinum, gold, titanium, brass, bronze, nitinol, and other alloys, as

well as semiconductors and other diverse materials, without the use of

solder or soldering flux.

The latest laser technology along with modern control

techniques and ease of maintenance are all combined in this pulsed

laser-welding system. This system is developed mainly for

micro-processing and, highly suitable for applications in research and

development as well as in small-scale manufacturing.

The welding system is available as a beam source (laser

class IV) or with a sealed processing chamber (laser class I). The

software of the laser welding system runs under the operating systems

Windows 95/98, Windows NT, and Windows 2000/XP.

The beam source is a pulse-driven Nd:YAG laser that emits

light with a wavelength of 1064nm. The laser energy is transmitter

through a quanrtz-glass fiber and is focused on approximately 100um.

Features:

�

High beam quality and efficiency even with the smallest

focal diameters

�

Flexible integration into a processing station with laser

class I for micro-processing

�

High system reliability through durable components and

low maintenance

Applications:

�

Micro-welding

�

Micro-drilling

�

Micro-perforating

�

Photo-labelling

�

Photo-induced reactions

Specifications:

|

Wavelength |

1064nm |

|

Pulse energy |

0-4000mJ |

|

Pulse width |

0.1-5.0ms |

|

Mode |

Multimode |

|

Focus diameter |

200um(standard optics), 100um/50um (special

optics) |

|

Output power |

5W (average) |

|

Charging power |

300W |

|

Pilot laser |

1mW at 633nm |

|

Pulse frequency |

1Hz at maximum energy |

|

Quartz-glass fiber |

200um core diameter, 1.5m length |

|

Cooling |

Internal, air-cooled water cycle |

|

Temperature range |

15�C-35�C |

|

Control unit |

Microprocessor with LCD display, separate control

panel, serial PC port, computer program for the control of all

laser functions. |

|

Dimensions |

520 x 520 x 280 mm |

|

Weight |

50kg |

|

Power source |

230V/115VAC � 10%, single phase, connected load

1kW |

Option 1: Stereo Microscope

In order to attain a very small focus, the beam of the

laser is coupled with a microscope. In this case, the high quality lens

of a Leica microscope is used to focus the laser beam. Thus, a

perpendicular observation of the workpiece is possible.

Option 2: Sealed Processing Chamber (Laser class I)

The sealed

processing chamber of laser class I allows for the manual positioning of

the workpiece. Inside the chamber there is a table with an adjustable

height that can be positioned in the focus of the microscope through the

use of two handles. The table has a thread-raster in order to fix the

sample holder or XY translation stage. The observation can take place

through the large protective window, the oculars of the microscope (with

integrated protective filters), or a monitor connected to an optional

CCD camera.

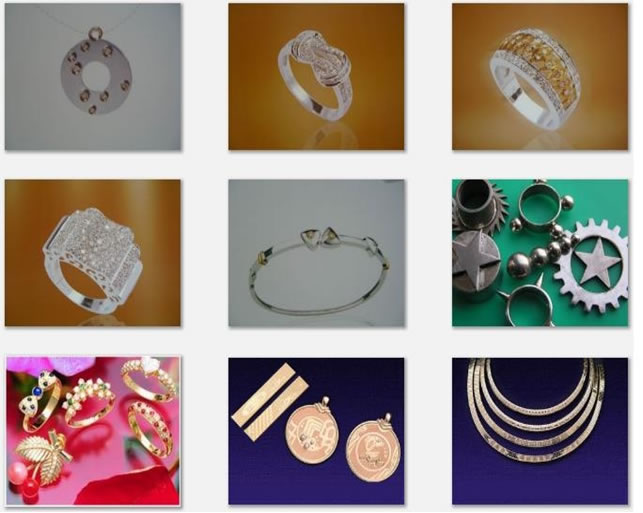

3. Welded Samples

|