STGLO-C-Green

Hollow-core Fiber

optimized for 500-700nm range.

|

Physical Properties |

|

Core

contour |

Hypocyclo�de |

|

Inner

core � |

63 μm � 1 |

|

Outer

fiber � |

300 μm � 3% |

|

Fiber

coating layer |

Primary polymer

coating |

|

Optical Properties |

|

Center

Wavelength |

800nm / 1600 nm |

|

Attenuation @ 532nm |

30 dB/km �10 |

|

Dispersion @ 532nm |

1.5 ps/nm.km � 0.5 |

|

Transmission Band** |

200 nm |

|

Mode

field Diameter |

24 μm � 1 |

|

3dB

bend loss radius |

10 cm � 2 |

**Attenuation

lower than 100 dB/km for the 500-700nm

|

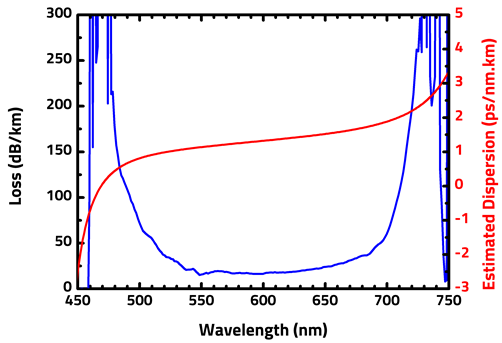

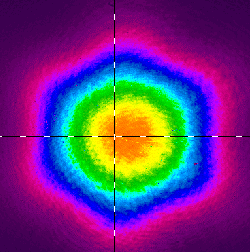

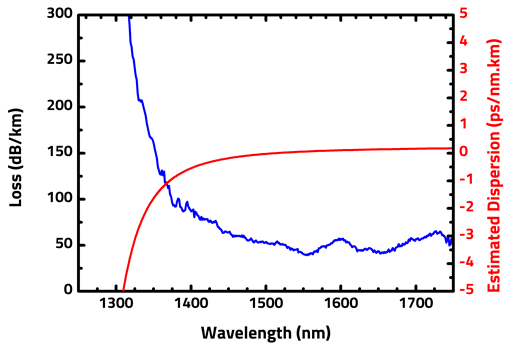

Typical attenuation and dispersion

|

|

|

|

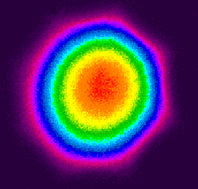

Output near field profile |

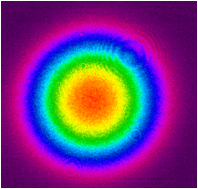

Output far field profile |

|

STGLO-C-TiSa_Er-7C

Kagome Hollow-Core

Fiber with optimized performance for 800nm and 1550nm. Ideal for Ti-Saph

and Erbium based lasers.

|

Physical Properties |

|

Core

contour |

Hypocyclo�de with

negative curvature parameter b=1* |

|

Inner

core � |

63 μm � 1 |

|

Outer

fiber � |

300 μm � 3% |

|

Fiber

coating layer |

Primary polymer

coating |

|

Optical Properties |

|

Center

Wavelength |

800 / 1600 nm |

|

Attenuation @ 532nm |

<80 dB/km �10 |

|

Dispersion @ 532nm |

1 ps/nm.km � 0.5 |

|

Transmission Band** |

>100nm / >300nm |

|

Mode

field Diameter |

44 μm � 1 |

|

3dB

bend loss radius |

5 cm � 2 |

**Attenuation

lower than 100 dB/km for the 1300-1750nm

|

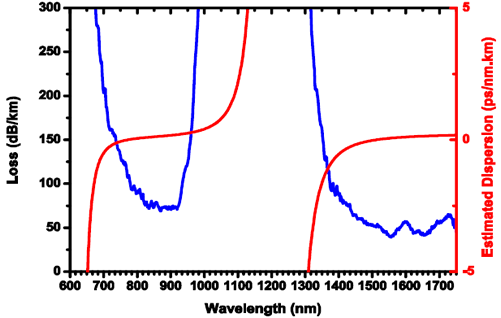

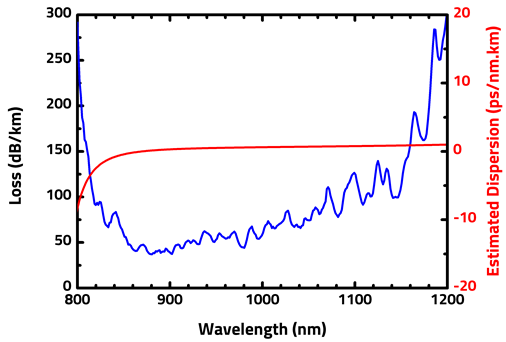

Typical attenuation and dispersion

|

|

|

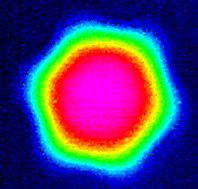

Typical output near field profile @ 800nm |

|

STGLO-C-Yb-7C

Hollow-Core Fiber optimized for 900-1100nm range. Ideal for Yb and

Nd:YAG based lasers.

|

Physical Properties |

|

Core

contour |

Hypocyclo�de with

negative curvature parameter b>0.7* |

|

Inner

core � |

57 μm � 1 |

|

Outer

fiber � |

320 μm � 3% |

|

Fiber

coating layer |

Primary polymer

coating |

|

Optical Properties |

|

Center

Wavelength |

1030 nm |

|

Attenuation @ 532nm |

<100 dB/km

|

|

Dispersion @ 532nm |

1 ps/nm.km � 0.5 |

|

Transmission Band** |

300 nm |

|

Mode

field Diameter |

39 μm � 1 |

|

3dB

bend loss radius |

5 cm � 2 |

|

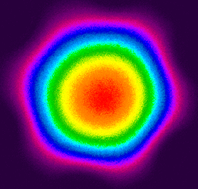

Typical attenuation and dispersion

|

|

|

|

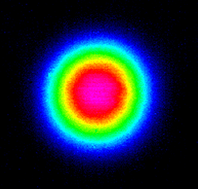

Output near field profile |

Output far field profile |

|

STGLO-C-Er-7C

Hollow-Core Fiber optimized for 1550nm.

Ideal for Erbium lasers.

|

Physical Properties |

|

Core

contour |

Hypocyclo�de with

negative curvature parameter b=0.8* |

|

Inner

core � |

61 μm � 1 |

|

Outer

fiber � |

432 μm � 3% |

|

Fiber

coating layer |

Primary polymer

coating |

|

Optical Properties |

|

Center

Wavelength |

1030 nm |

|

Attenuation @ 532nm |

<100 dB/km

|

|

Dispersion @ 532nm |

1 ps/nm.km � 0.5 |

|

Transmission Band** |

300 nm |

|

Mode

field Diameter |

39 μm � 1 |

|

3dB

bend loss radius |

5 cm � 2 |

|

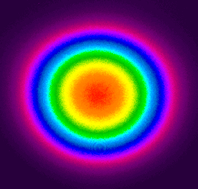

Typical attenuation and dispersion

|

|

|

|

Output near field profile |

Output far field profile |

|

STGLO-C-2μm-7C

Hollow-Core Fiber optimized for 2-3μm range.

|

Physical Properties |

|

Core

contour |

Hypocyclo�de with

negative curvature parameter b>0.7* |

|

Inner

core � |

56 μm � 1 |

|

Outer

fiber � |

415 μm � 3% |

|

Fiber

coating layer |

Primary polymer

coating |

|

Optical Properties |

|

Center

Wavelength |

2000 nm |

|

Attenuation @ 532nm |

60 dB/km

|

|

Dispersion @ 532nm |

1 ps/nm.km � 0.5 |

|

Transmission Band** |

>350 nm |

|

Mode

field Diameter |

42 μm � 1 |

|

3dB

bend loss radius |

5 cm � 2 |

|

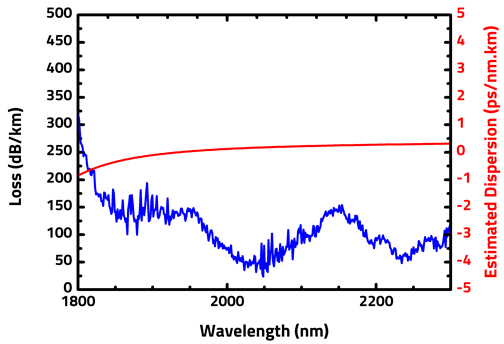

Typical attenuation and dispersion

|

|

|

|

Output near field profile |

Output far field profile |

|

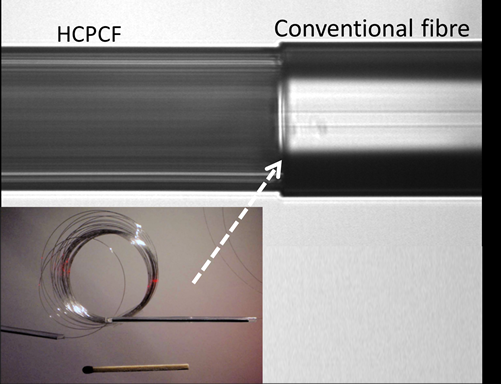

STGLO PHOTONIC MICROCELL�

Photonic Micro-Cell (PMC)� technology is

based on Hollow-Core Photonic Crystal Fiber (HC-PCF) and the process of

filling the fiber with a chosen gas to offer photonic functionalities

such as (i) Optical frequency conversion, (ii) Ultra-high power pulsed

laser delivery (iii) Laser pulse compression or (iv) Frequency

standards.

A PMC is a stand-alone and modular component that consists of a HC-PCF

filled with gas and fiber terminations. The presence of gas within an

optical fibre on a micron scale provides a million-fold increase in the

gas-laser efficiency compared to traditional lasing methods and opens up

the unique ability for functionalization. For example, with a Raman gas

one can produce new wavelengths and hence create new applications. There

are different variants of HC-PCF used within the PMC family of

components. The Inhibited-Coupling guiding HC-PCF such as Kagome fiber

produces particularly good results with a high damage threshold and a

very wide bandwidth.

The PMC comes in different forms tailored to either the applications or

the laser power requirements or to specific housing requirements. Below

is a list of the different PMC forms we can deliver

|

PMC-TERMINATION TYPE |

FEATURES / APPLICATIONS |

|

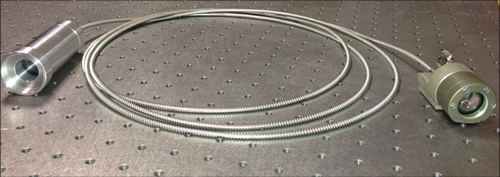

ALL-FIBER PMC |

|

|

An optical fiber made of a length of HC-PCF

filled with gas and spliced to a solid optical fiber.

- Gas type: Typically any molecular

gas. Atomic vapor

- Gas pressure ranges: from High

vacuum pressure to several bars.

- Splice loss: typically 1

dB/splice.

- Ideal for low power laser

applications such as telecommunications,

instrumentations, frequency standards, Frequency

conversion.

|

|

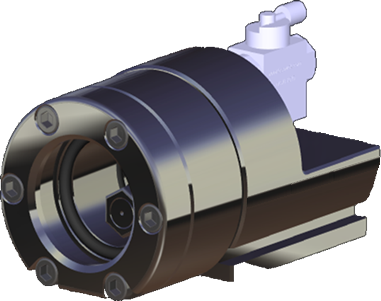

GAS-FILLABLE & TRAVEL STAGE MOUNTABLE

PMC-TERMINATION |

|

|

This PMC has at least one of its

terminations exhibiting a gas-fillable cell. This cell is

mountable on standard translation stages for quick and

efficient laser coupling.

- Gas injection

- Rugged tube-over-fiber

- Micro-bending elimination

- Macro-bending restraint

- Dust contamination prevention

- Ideal for high power applications

such as ultra-short pulse laser beam delivery, laser

pulse compression, frequency converter.

|

|

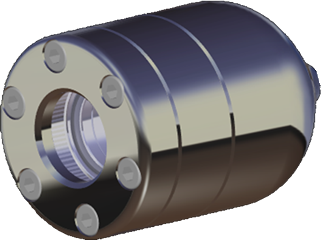

TUBULAR CELL PMC-TERMINATION |

|

|

This PMC has at least one of its

terminations exhibiting a tubular cell. This cell can be

mounted on and/or integrated in standard opto-mechanical

holders or systems.

|

Laser doppler vibrometer

Laser doppler vibrometer |