1. Background

information about laser diodes

Laser diodes are an

ever-increasing part of everyday life. Indeed, when people go through the course

of a single day of their lives, they will encounter perhaps hundreds or even

thousands of laser diodes. Commonplace examples of the use of laser diodes

include CD and DVD drives, barcode scanners, laser pointers, construction

alignment devices, and police traffic radar.

Most laser diodes

can be easily damaged if their nominal voltage or current parameters are

exceeded. In fact, products that contain laser diodes often seem to mysteriously

fail, with no apparent provocation. A close examination into the failure modes

of these devices has revealed power surges during power-up/power-down sequences

and electrostatic discharge (ESD) events as two major causes of laser diode

failure.

Power-up/power-down failures

When power is being

turned on or off on a product, internal circuits can be operating outside their

intended internal power supply range for a brief period of time. As one example,

rail-to-rail operational amplifiers used in laser diode drivers may be specified

to operate with power supplies ranging from 2.7 to 5.5 volts. But the

manufacturer makes no guarantee or representation regarding what the operational

amplifier will do between a supply voltage of 0 and 2.7 volts. Because of this,

current or voltage regulation circuits may go out of balance during power-up and

power-down, and often apply an over-current or over-voltage condition to the

laser diode that is integrated within the product. These over-current or

over-voltage conditions may stress the laser diode, such that each power-up or

power-down cycle accumulates in the form of device fatigue. Eventually, the

laser diode may fail from the fatigue, leading to what the user experiences as a

mysterious failure.

Electrostatic

discharge failures

Electrostatic

discharge (ESD) may also cause mysterious device failures, and there are many

ways in which ESD might come in contact with a product. One of the most common

ways that ESD is generated occurs when a person walks across a carpeted floor,

and then touches something. A discharge can occur to anything being touched,

ranging from things that are not sensitive to ESD, such as doorknobs, to things

that are very sensitive to ESD, such as electronic products. Studies have shown

that, when an ESD discharge occurs, the discharge voltage can range anywhere

between 4,000 and up to as much as 32,000 volts DC, depending on environmental

conditions, clothing being worn, type of flooring surface, and other factors.

When an laser diode that is designed to operate with a terminal voltage of 2.2

volts experiences an ESD discharge of thousands of volts, the result can be

immediately destructive. Alternatively (and what happens more commonly), the

laser diode will have some latent damage, with dramatically reduced lifetime.

Later, when it fails in the field, the user will often blame it on infant

mortality or some other cause, not realizing that the actual damage began

earlier in the product's lifetime.

2. Laser diode

damage mechanisms

Laser diodes

typically fail as the result of two distinct damage mechanisms:

Optical

overstress

One of the damage

mechanisms is optically related, and occurs when the laser diode is producing

light (referred to as “lasing”), and the optical energy density exceeds the

laser diode’s integral mirrors’ reflective capacity. When this occurs, the

mirrored surface permanently loses its reflectivity, and the laser diode no

longer functions properly. In layman's terms, this could be thought of as the

laser light becoming so intense that it "vaporizes" the mirror surface.

Electrical

overstress

The second damage

mechanism is related to failure of a laser diode’s P-N junction itself. A severe

over-current or over-voltage power surge can cause localized heating and other

harmful phenomena, which, under extreme conditions, can actually fracture the

laser diode die (we have seen this under a microscope, brought on by high levels

of ESD).

Both of these

damage mechanisms can be provoked by an over-voltage or over-current condition.

Low-power laser diodes, that is, laser diodes whose optical output power is

below around 200 mW, are particularly sensitive to ESD. This is because they are

designed to be inherently fast devices. Indeed, low-power laser diodes are often

directly modulated and used for fiber-optic communication with data rates in the

gigahertz range. Thus the P-N junction and optical elements of a laser diode can

react very quickly to changes in voltage or current.

Therefore, in order

to be effective, an ESD protection device and method should preferably be

implemented as a proactive measure, by preventing the over-voltage or

over-current condition from happening in the first place, not by reacting to it

once it has occurred.

Current vs.

voltage profile

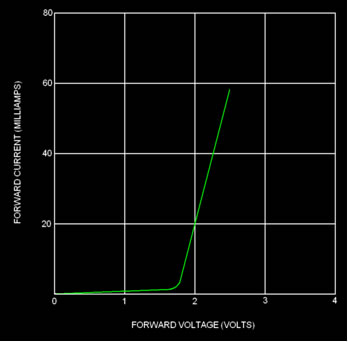

The figure to the

right shows the current vs. voltage profile of a typical low-power laser diode.

It can be seen that the profile is similar to other types of diodes and

semiconductor devices.

Starting from zero

volts, applying incremental positive increases in voltage (i.e., those voltages

that would tend to forward bias the laser diode), very little current flows

until around 1.8 volts is reached.

Further incremental

positive increases from around 1.8 volts causes current flow to increase at a

roughly exponential rate. However, the laser diode does not emit laser light

until the current exceeds a “lasing threshold,” which, for the laser diode

referred to here, occurs at around 30 milliamps and at around 2.2 volts. With

further incremental positive increases in voltage, current flow continues to

increase, while the optical power emitted by the laser diode increases at a rate

that is roughly proportional to current.

Once the maximum

design current for a particular laser diode is reached (which is around 35

milliamps and 2.4 volts for this laser diode), further increases in current will

likely result in failure, caused by one or both of the damage mechanisms

described above. Thus it is important to completely prevent voltage, and thus

current, from increasing beyond the absolute maximum rating for a particular

diode. In most cases, a low-power laser diode will be destroyed if the absolute

maximum ratings are exceeded, even for a brief period of time.

Note that the

figure shows only the current vs. voltage profile for positive voltages, that

is, voltages that would forward-bias the laser diode. Laser diode manufacturers

recommend that negative voltages, that is, voltages that would tend to

reverse-bias the laser diode, be avoided.

The data sheet for

an exemplary laser diode lists an absolute maximum reverse voltage of 2 volts.

In order to protect this laser diode from being damaged by ESD, the protection

means should limit positive voltages to around 2.4 volts and negative voltages

to around 2.0 volts or less. These voltages are used as a reference throughout

the rest of this discussion.

3. The LASORB

solution

To solve the ESD

problem, in 2008 we developed an electrical component called LASORB. The word

LASORB is a combination of the words “LASER” and “ESD ABSORBER”. The LASORB

component is easy for engineers to implement because it is small and can simply

be connected directly to the pins of the laser diode.

How LASORB works

LASORB's primary

means of protection is a slew-rate detector that monitors the voltage across the

pins of the laser diode. If there is a fast change-of-voltage condition

detected, this triggers LASORB to aggressively conduct the voltage (and thus

current) away from the laser diode. The conduction is initiated very rapidly –

in some cases less than one nanosecond. The conduction can last from several

microseconds, to tens of microseconds.

The

change-of-voltage approach is a very good principle to use for laser diodes

because, under ordinary circumstances, even during modulation the voltage across

laser diode pins does not change very much. Therefore any change of voltage –

especially a fast change of voltage – is an abnormal event, something that

happens only during ESD or other types of electrical faults.

Customizable to

match diode requirements

To allow for

complete flexibility and customization of individual laser diode requirements,

the LASORB component is implemented as a hybrid, containing active silicon and

passive components. And as a side-effect of the makeup of this hybrid component,

LASORB also offers protection from reverse bias conditions, thus allowing LASORB

to offer complete protection of the laser diode from a variety of electrical

faults.

LASORB is available

as a small, through-hole component, which costs between $2 and $8, depending on

the quantity. Engineers can choose from several LASORB part numbers that dictate

the actual slew rate, surge conduction time and maximum operating voltage.

4.

LASORB datasheets

There

are several standard LASORB formulations -- optimized for IR, Red, Blue and BLU-RAY

laser diode use, as well as series-connected strings and QCLs.

L44-208-X series optimized for very sensitive Red and IR laser diodes

L44-228-X series optimized for Red and IR laser diodes

L44-392-X series optimized for high power Red diodes

L44-916-X series optimized for Green laser diodes

L44-683-X series optimized for Blue laser diodes

L44-833-X series optimized for BLU-RAY laser diodes

L44-2000-X series optimized for series-connected strings and Quantum Cascade

Lasers

We

can also provide custom LASORB formulations. LASORB has several degrees of

freedom that we can tune to optimize the device to a particular laser diode

operating voltage and modulation requirement.

Please contact us for the detailed data sheets.

Diode Bar

Diode Lasers

Diode Bar

Diode Lasers |